You’re thinking about ways to reduce utility costs for your company? A Combined Heat and Power (CHP) may be an option to achieve that goal. The first step you will need to do is make an initial review which considers your plant’s heat and power needs and the system design and engineering requirements and limitations. Below highlights many of these design and engineering considerations.

CHP Plant Owned and Operated by Host Site:

- Option 1 – Electrical power generation less than site load – Requires agreement with LDC for back-up power and fault levels.

- Option 2 – Electrical power generation exceeds the site load with export of surplus power – Requires a Contract with the Provincial Authority – Requires connection assessment.

- May run 24/7 or be cycled to suit thermal loads, generation economics or Export Contract.

CHP Plant Owned by Independent Power Producer (IPP):

- Contract with host for thermal output (usually hot water or steam).

- Contract with Provincial Authority for the electrical power. Recent offers such as CHPSOP and CHP IV favored peak workday dispatch.

- CHP may use host auxiliary systems such as back-up boilers, water treatment plant, deaerator, etc. or replace them in the new facility.

General CHP Strategies:

- CHP Plant Owned and Operated by Host Site: – Option 1 – Electrical power generation less than site load and requires agreement with LDC for back-up power and fault levels. Option 2 – Electrical power generation exceeds the site load with export of surplus power – Requires a Contract with the Provincial Authority and Requires connection assessment. May run 24/7 or be cycled to suit thermal loads, generation economics or Export Contract.

- CHP Plant Owned by Independent Power Producer (IPP): Contract with host for thermal output (usually hot water or steam). Contract with Provincial Authority for the electrical power. Recent offers such as CHPSOP and CHP IV favored peak workday dispatch. CHP may use host auxiliary systems such as back-up boilers, water treatment plant, deaerator, etc. or replace them in the new facility.

CHP Integration with Host Site

- Space: Is there spare space for the facility or is new property required nearby? A remote location would require longer interconnection pipe headers

- Operation of the Plant: By Host operators or by IPP operators?

- Host Thermal Load (Steam and/or Hot Water): Daily load fluctuations, Seasonal load fluctuations. Required thermal supply reliability may dictate running reserve boiler capacity at minimum to assume load during CHP outage.

- Electrical Load: Behind-the-meter CHP limited by host load and may need to modulate. Grid connected CHP typically constrained by host thermal load and target heat rate.

- Fuel (Typically Natural Gas): Combustion turbines typically require a booster compressor. Utility may need to upgrade service for incremental load.

- Environmental: New or existing stack? Dry low emissions or after-treatment to reduce NOx and CO limits? Permits.

Generating Equipment Options

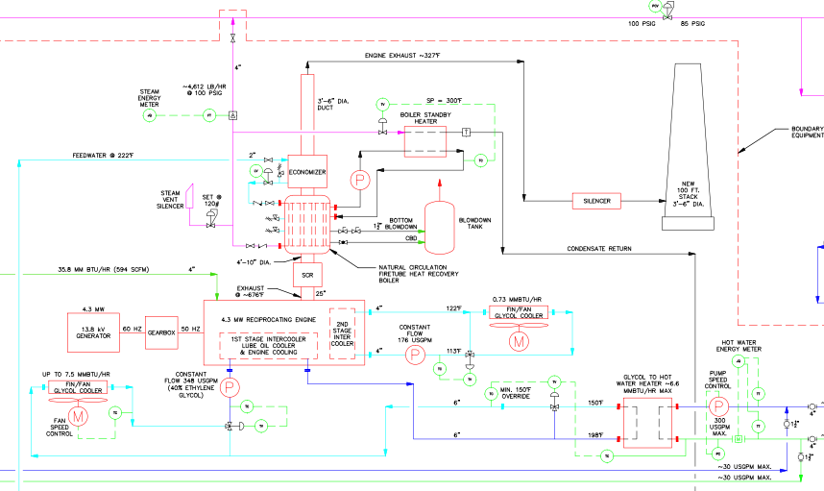

- Reciprocating Genset: Use jacket and intercooler loads to generate hot water. Use exhaust to supplement hot water production, top up water temperature or generate steam. Typically 200 kW to 6 MW total plant generation with one or more gensets.

- Gas Turbine Generator: Use GTG exhaust to generate steam and/or hot water. Typically 3 MW to 120 MW total plant generation (but some larger up to 500 MW) with one or more GTG’s and an STG if a combined cycle.

- Steam Turbine Generator: Typically high pressure superheated steam at inlet from conventional boiler or from CHP heat recovery steam generator (in combined cycle). CHP steam pressures and temperatures typically lower than for modern combined cycle generation stations. If back pressure STG, exhausts to host conditions. If extraction STG, extraction supplies host and STG exhaust is condensed.

Heat Recovery Methods

- Firetube Boiler: Hot exhaust gases pass through inside of tubes. Limited to Recip Gensets and smaller GTG’s.

- Water Tube Boiler: Hot exhaust hot gases pass over outside of tubes, often with fins for enhanced heat recovery. Heat recovery steam generator (HRSG) has a steam drum (evaporator) with level control. Once through steam generator (OTSG) has no drums. Water flows through parallel circuits of serpentine tubes, feedwater transitions to saturated steam and then exits at superheated steam conditions. Uses flow control with temperature trim. Requires ultra-pure water. May have more than one steam pressure.

- Supplemental Heat Recovery Options: Superheater. Feedwater Economizer. Hot Water Heater for process water, make-up water or condensate return. Glycol systems.

Acceptable Host Thermal Loads for Heat Rate Calculations

- Acceptable Loads: Building Heating, Domestic Hot Water, Process loads, Absorption Chillers for process needs only. (Offset of electrical chiller load is not permitted in heat rate calculations).

- Non-acceptable Loads: Loads already allocated to an existing CHP, Condensing STG LP steam, GTG combustor injection steam, Steam used within the thermal cycle of the CHP plant.

Performance Augmentation Options

- Inlet Chilling for enhanced GTG performance on hot days: Evaporative Cooling – Trays or Sprays. Chilled Water (…but chiller load is subtracted from total)

- Combustor Steam Injection: Boosts power and lowers NOx, but worsens heat rate since steam consumption cannot be included as thermal load.

- Supplement steam supply with process heat recovery improves heat rate and described as “Enhanced CHP”.

Heat Rate Formulas

- Expressed in HHV or LHV terms: OEM heat rates typically LHV basis, but Provincial Authority Targets typically HHV basis. For natural gas LHV = 0.9 x HHV.

- Effective Heat Rate: (CHP Fuel Energy – Boiler Plant Fuel Energy Displaced) / Net Power. Ontario CHPSOP Target was < 4980 Btu/kWhr Winter to 7400 Btu/kWhr Summer for seasonal plant or 6000 Btu/kWhr non-seasonal plant HHV basis. Typical large combined cycle power plant (non-CHP) has heat rate of ~7000 Btu/kWhr HHV.

- Class 43.1 Heat Rate: CHP Fuel Energy In / (Gross Power + Useful Heat Output) < 6000 Btu/kWhr HHV to qualify.

- Useful Heat Output: (Steam + HW Energy Delivered to Host) – Energy Returned from Host.

Recent Comments